Samsung Biologics Showcases Cell Line Development Platform at BioProcess International Conference

Last year, a global contract development and manufacturing organization (CDMO), Samsung Biologics launched two new drug development platforms: S-DUAL™, for bispecific antibodies, and DEVELOPICK™, for developability assessment, at the BioProcess International conference. At this year’s conference, held in September in Boston, the CDMO showcased the success of these platforms and highlighted its cell line development capabilities.

The conference featured a presentation from Janet Lee, Director of Cell Line Development at Samsung Biologics. Lee discussed S-DUAL™ and the importance of choosing the right cell line for the production of bispecific antibodies — molecules with two distinct antigen-binding sites that enable simultaneous interaction with multiple molecular targets.

Samsung Biologics has developed a proprietary Chinese hamster ovary (CHO) cell line, S-CHOice®, which it uses to help clients produce a range of therapeutics.

How Does Cell Line Development Work?

Cell line development is a pivotal step in biotherapeutic manufacturing. The journey begins with the selection of a suitable cell line, which is commonly composed of CHO cells. These cells are known for their easy editability and high yield of proteins. The objective is to create a stable, high-producing cell line that can serve as the workhorse in manufacturing molecules like monoclonal antibodies or bispecific antibodies. The candidate cell is engineered in the lab to express the desired therapeutic antibody.

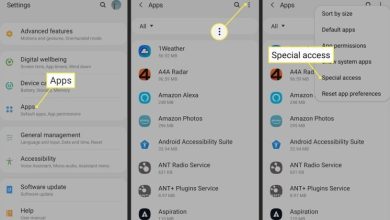

During the screening and selection phase, Samsung Biologics uses its DEVELOPICK™ platform to facilitate the identification and isolation of high-producing cells. The CDMO uses a high-throughput technique to assess large volumes of individual cells based on their productivity and genetic stability. The selected cells then undergo rigorous testing to ensure they uphold the desired traits over extended periods, thereby promising a reliable supply of therapeutic proteins.

The Importance of Early Stage Assessment

At the optimization stage, developers can tweak the cell culture conditions to maximize the yield, but there is value in early stage assessment to avoid delay or costly adjustments at this stage, explains a lead scientist from Samsung Biologics in a recent white paper.

Early stage assessment is “part of the larger industrywide trend of building systems and processes early in a project’s life cycle (i.e., before and during Phase 1) that enable success for later-stage development,” says Daniel Buckley, Lead Scientist in CDO downstream at Samsung Biologics.

“In parallel, work must be done to prepare development and manufacturing for that later stage, whether to enable studies or to commercialize the product. It is a seamless transition between early and late-stage development that leads to time and cost savings.”

This sentiment was echoed in a poster used to demonstrate DEVELOPICK™. The poster describes two case studies of drug candidates used by the platform.

“Gaining early insights into the stability of candidate drug molecules can help save valuable time and costs,” it reads. “In both case studies, predictions were made to evaluate and compare the developability of multiple candidate molecules. In Case Study A, Samsung Biologics was able to exclude the candidate with low stability from an early stage. Likewise, in Case Study B, a molecule with higher developability was selected based on sequence liability, thermal stability, and chemical stability analysis results.”

The Bigger Picture for Samsung Biologics

Samsung Biologics didn’t just focus on cell line development at BioProcess 2023. It also discussed its most recent expansion of facilities and its plans for a new Bio Campus. Construction of Bio Campus II began in early 2023, as the CDMO broke ground on its fifth manufacturing facility at its headquarters in Songdo, South Korea.

“Given the continuing increase in the demand for outsourced manufacturing of biopharmaceuticals, we are proactively making this investment in alignment with our growth strategy to further strengthen our standing as a leading CDMO,” said John Rim, President and CEO of Samsung Biologics in a statement announcing the beginning of construction of Plant 5. “The new facility will enable us to provide our customers with even greater innovation and services that will increase speed to market and flexibility.”

Plant 5 is expected to be up and running by April 2025. It will increase Samsung Biologics’ manufacturing capacity by 180,000 liters, reaching an industry-leading total of 784,000 liters. The investment in Plant 5 is significant, over 1.9 trillion South Korean won (about $14 billion), and is part of a larger 7.5 trillion won investment in Bio Campus II.

The new campus, covering 360,000 square meters (around 89 acres) of land acquired in July 2022, is intended to become a center for large-scale manufacturing and innovation. In addition to hosting Plant 5, Bio Campus II will include more large-scale plants and an open innovation center.